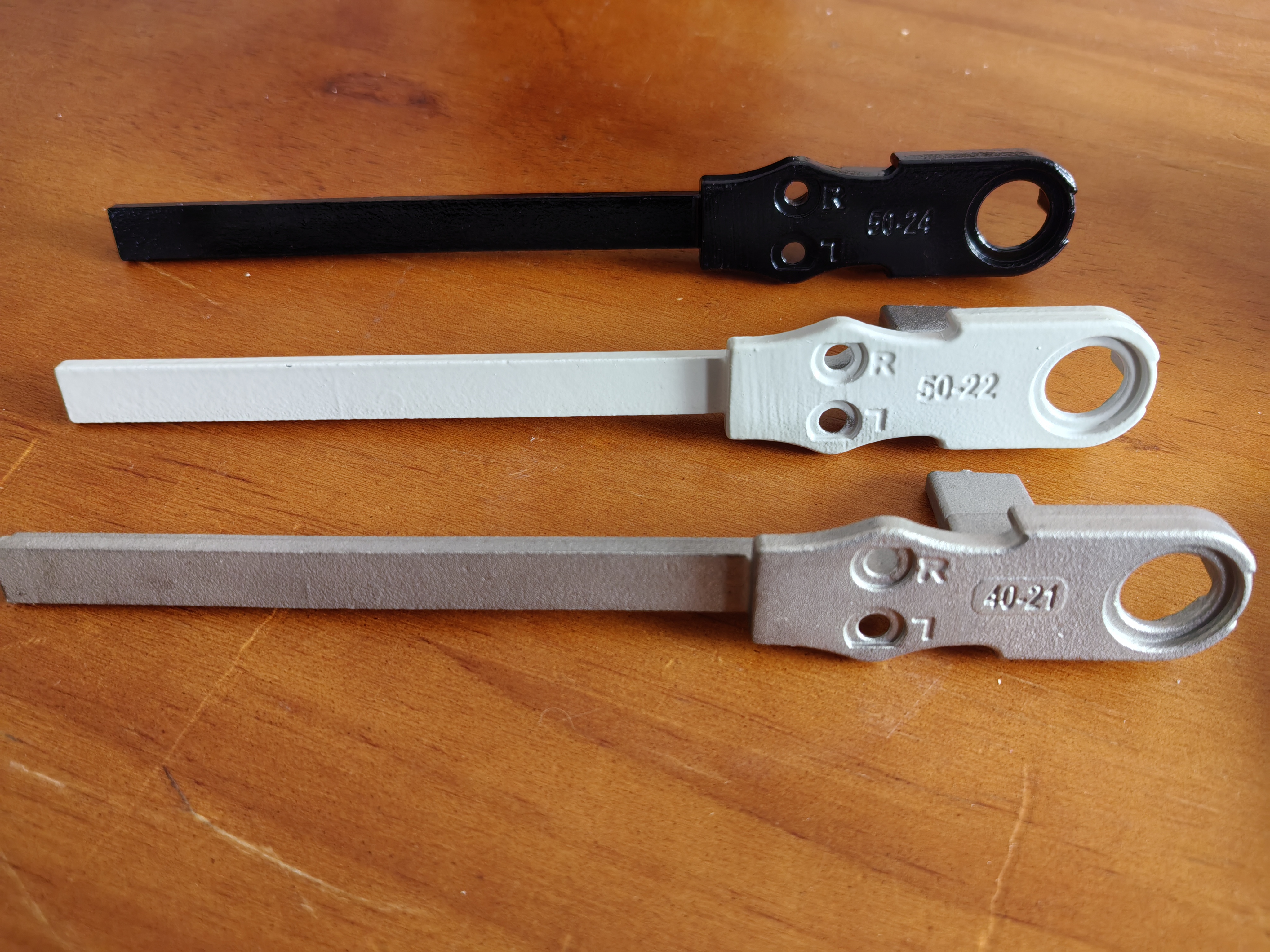

Mejore su ingeniería: descubra el poder de la fundición de precisión de acero inoxidable para piezas deslizantes mecánicas

En el mundo de la ingeniería de precisión, donde cada milímetro y cada movimiento cuentan, la elección del material y el proceso de fabricación son fundamentales. Para piezas mecánicas deslizantes, que exigen un movimiento impecable, una durabilidad excepcional y una fiabilidad inquebrantable, fundición de precisión de acero inoxidable surge como la solución definitiva.

¿Por qué fundición de precisión de acero inoxidable? La combinación insuperable.

El acero inoxidable, reconocido por sus propiedades superiores, es un material ideal para componentes mecánicos deslizantes. Al combinarse con la técnica avanzada de fundición de precisión (o fundición a la cera perdida), el resultado es una pieza que supera las expectativas de rendimiento y durabilidad.

He aquí por qué esta combinación es revolucionaria:

- Resistencia a la corrosión incomparable: Las piezas mecánicas de la corredera suelen operar en entornos exigentes, expuestas a humedad, productos químicos y temperaturas variables. El contenido inherente de cromo del acero inoxidable crea una capa de óxido pasiva que proporciona una resistencia excepcional a la oxidación y la degradación química. Esto garantiza que las piezas de la corredera mantengan su integridad y un funcionamiento fluido, incluso en condiciones corrosivas.

- Resistencia y durabilidad excepcionales: El acero inoxidable ofrece alta resistencia a la tracción, dureza y resistencia al impacto. La fundición de precisión mejora aún más estas propiedades al permitir una estructura de grano óptima y minimizar los defectos internos. Esto significa que sus piezas deslizantes pueden soportar cargas pesadas, fricción constante y movimientos repetitivos sin comprometer su rendimiento, lo que prolonga su vida útil y reduce el tiempo de inactividad.

- Precisión y exactitud dimensional: La fundición de precisión es un proceso de fabricación de forma casi final, capaz de producir geometrías complejas con tolerancias extremadamente ajustadas. Esto es crucial para las piezas mecánicas deslizantes, donde un ajuste preciso y un movimiento suave y constante son esenciales. La alta precisión dimensional lograda mediante este método a menudo minimiza o incluso elimina la necesidad de un costoso mecanizado secundario, lo que le ahorra tiempo y recursos.

- Acabado superficial superior: La fundición de precisión proporciona un excelente acabado superficial, esencial para que las piezas deslizantes reduzcan la fricción y el desgaste. Una superficie más lisa garantiza un movimiento fluido, minimiza la necesidad de lubricación y prolonga la vida útil tanto de la pieza deslizante como de los componentes acoplados.

- Libertad y complejidad del diseño: A diferencia de los métodos de fabricación tradicionales, la fundición de precisión permite la creación de formas complejas e intrincadas, incluyendo canales internos, socavones y detalles finos. Esta flexibilidad de diseño permite a los ingenieros optimizar la funcionalidad y la eficiencia de las piezas mecánicas deslizantes, lo que da lugar a soluciones innovadoras.

- Resistencia al calor: El acero inoxidable mantiene su integridad estructural y sus propiedades mecánicas incluso a temperaturas elevadas, lo que lo hace adecuado para aplicaciones deslizantes en entornos de alta temperatura.

- Rentabilidad para piezas complejas: Si bien el costo inicial de las herramientas puede parecer mayor que el de otras alternativas, el proceso de fundición de precisión suele resultar más rentable a largo plazo. La capacidad de producir piezas complejas con un mecanizado mínimo posterior a la fundición reduce significativamente los costos generales de producción y los plazos de entrega.

Aplicaciones donde la precisión importa:

Las piezas deslizantes mecánicas fundidas con precisión en acero inoxidable son indispensables en una amplia gama de industrias y aplicaciones, que incluyen:

- Automotor: Correderas de asientos, mecanismos de ventanas, componentes de motor.

- Dispositivos médicos: Instrumental quirúrgico, equipos de diagnóstico, automatización de laboratorio.

- Automatización industrial: Robótica, sistemas de transporte, unidades pick-and-place.

- Procesamiento de alimentos: Correderas higiénicas y resistentes a la corrosión para maquinaria.

- Aeroespacial: Mecanismos de superficie de control, componentes del tren de aterrizaje.

- Máquinas herramientas: Guías lineales de precisión, portaherramientas.

- Maquinaria de embalaje: Componentes que requieren movimiento repetitivo y de alta velocidad.

Elija la excelencia para sus sistemas de movimiento.

Si sus aplicaciones de correderas mecánicas exigen el máximo rendimiento, durabilidad y precisión, la fundición de precisión de acero inoxidable es la solución. Es una inversión en fiabilidad, eficiencia y ahorro de costes a largo plazo. Asóciese con un fabricante de confianza que comprende las complejidades de este proceso avanzado para aprovechar al máximo el potencial de su próximo proyecto.